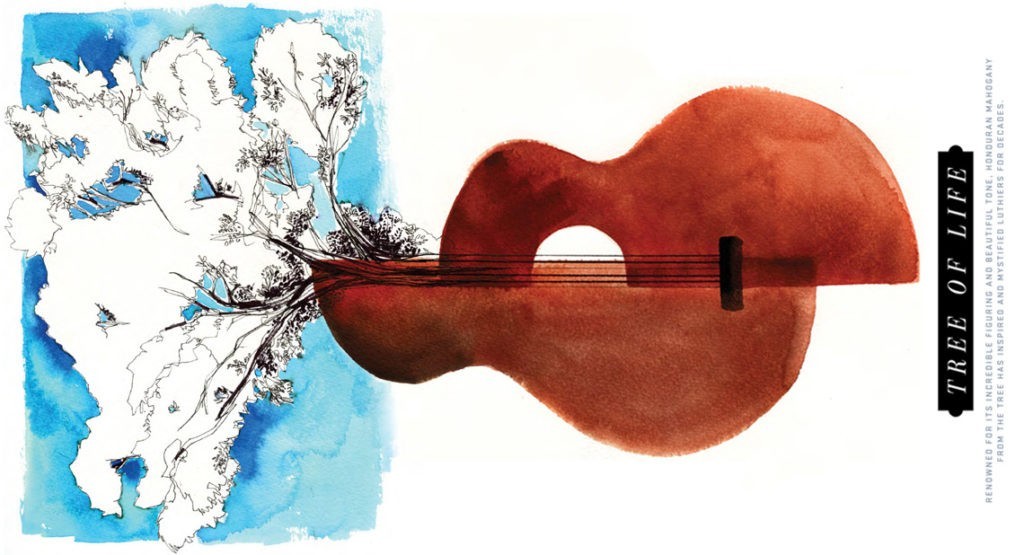

“The Tree”

One day last summer, I sat with a guitar case at my feet, awaiting a return flight from the Healdsburg Guitar Festival in Santa Rosa, California. An older gentleman seated next to me was eyeing the case with a look that suggested he wanted to talk about instruments. Upon making an introduction, he unzipped his overnight bag, rifled inside it for a moment, and retrieved an object whose identity was obscured by Saran Wrap. Looking around nervously, as if conducting an illicit transaction, he carefully peeled away a bit of the covering to reveal a luminous brown portion of wood with the most intricate wavy figuring. “This,” he said, with a twinkle in his eyes, “is The Tree!” As it happened, the gentleman was a seasoned woodworker new to guitar making. He’d gotten his hands on some singular quilted mahogany that for years has driven many woodworking and guitar enthusiasts to distraction. Unlike ordinary mahogany—the straight-grained and reddish-brown stuff— this timber is unique in its appearance, with heavy figuring that is thought to be the result of a genetic defect. Adding to its allure is the fact that this quilted mahogany, which has been used by Bedell/Breedlove, Lowden, Santa Cruz, R. Taylor, and other makers, is from a single tree—The Tree, as it has been dubbed— that has a long and fascinating story.

The legend of The Tree began almost 50 years ago, when a group of loggers deep in the Chiquibul Jungle of Honduras, now Belize, discovered a giant mahogany tree, 100 feet tall, with a 10-foot base and spiraled bark that gave a hint of its intense figuring. When the loggers felled the tree by ax, in 1965, things went terribly wrong. Against their expectations, it landed in a ravine, where it proved impossible to extricate even after being halved by a tractor. The tree had been resting in the ravine for more than a decade when sawmill owner Alan Mauney rediscovered it. He brought it to the attention of Robert Novak, an American wood importer who happened to be in the area in search of rosewood. Flooding prevented them from visiting the fallen tree for a month. When Novak at last encountered it, he immediately sensed its magnificence and entered a protracted bidding war that involved several other parties. The nature of their business ended up working out in his favor.

“The other bidders wanted the wood for the purpose of veneering, and they had a lot more money at their disposal than I did,” Novak says. “But after about a year, they became afraid that, because the tree had been down for so long, it wouldn’t veneer well. So, around 1981, I ultimately won out.” Novak then faced the challenge of how to remove the tree. A clever solution was devised: the two felled logs were quartered with chainsaws where they lay. The wood was dragged out of the ravine and trucked, three pieces at a time, 100 perilous miles through the jungle to the Chiquibul River. There, a loader slowly pushed it, piece by piece, into the river and pulled it the final 100 feet to the carriage ramp of an ancient steam-powered sawmill. Novak, who oversaw all of the milling, finally got a glimpse of the tree’s intense figuring when it

was flat sawn. “There was a strong wow factor,” he says. “It was some of the prettiest wood I’d ever seen in my life. And it still is.”

The Tree’s dramatic figuring is classified in three main categories. One pattern resembles a tortoise shell, its triangular shapes having dark veiny outlines. Another is often referred to as a sausage quilt, as its wide horizontal patterns bear a resemblance to links of that product, with rolling vertical lines that look like long, wavy tendrils. The third type of figuring is blistered, which, with its effusion of irregular curly shapes, is the wildest variation. While all three varieties are dazzling, the tortoise-shell pattern is most wildly coveted by guitar makers and their clients. The milling operation for Novak’s wood stretched out for nearly two weeks and yielded 12,000 board feet of timber. (A board foot is 12 inches by 12 inches by one inch, or its volumetric equivalent.) The cut wood was then shipped to Miami, where, due to its density, it was kiln dried for 30 days rather than the standard dozen. It was then carefully stored and sold from a warehouse in Miami as well as through Handlogger’s Hardwoods, in Sausalito, California.

Nylon-string luthier Mark Berry, then a woodworker and avocational musician, recalls his first impressions of the wood. “I remember going to Handlogger’s and seeing the wood when it had just come in,” he says. “It looked incredible, but starting at 10 dollars per board foot, I thought it was outrageously expensive.” Today, wood from The Tree sells for as much as $1,500 per board foot. Initially, however, it

failed to make a strong impression on the guitarbuilding community, as mahogany was still considered a commonplace, budget tonewood.